个人资料

教育经历• 2005/08–2010/01 香港中文大学博士 • 2002/09–2005/07 厦门大学理学硕士 • 1998/09–2002/07 湖南师范大学理学学士 工作经历• 2017/02 - 华东师范大学 研究员 • 2015/08–2020/12 华东师范大学 紫江青年学者 • 2012/08–2015/07 华东师范大学 副教授 • 2010/02–2012/07 香港理工大学 博士后 个人简介华东师范大学精密光谱科学与技术国家重点实验室研究员。2010年获香港中文大学理学博士学位,之后在香港理工大学从事博士后研究工作,2012 年加入华东师范大学物理系,2015年获华东师范大学紫江青年学者项目支持。2015,2018年先后赴美国莱斯大学和澳大利亚昆士兰大学开展合作研究。长期从事低维碳材料结构、性质以及生长机制的理论研究,揭示了若干类型低维碳纳米材料的关键生长机制,提出的理论被国内外多个课题组的后续实验结果证实。近年来主持国家自然科学基金三项,,上海市人才项目一项,参与国家重大研究计划一项。发表学术论文60 余篇,其中以第一或通讯作者发表的论文包括Nat. Mater.,Nat. Electron.; Phys. Rev. Lett.,J. Am. Chem. Soc.,Nano Today, Angew. Chem. Int. Ed., Nano Letters,Sci. Adv., Adv. Funct. Mater.等。 课题组成员

魏文娅(博士) 殷玉玲(博士) 梁家毓(博士) Email: 1578621961@qq.com Email: yinyulyin@163.com Email: 313550213@qq.com

郭艳卿(博士) 陈瑶(硕士) 刘德鑫(硕士) Email: guoyq7057@163.com Email: 1761607372@qq.com Email: 2413027114@qq.com 已毕业学生

王丹霞(硕士) 刘逸凡(硕士) 补赛玉(博士) 赵威(硕士) 姜忍(硕士)

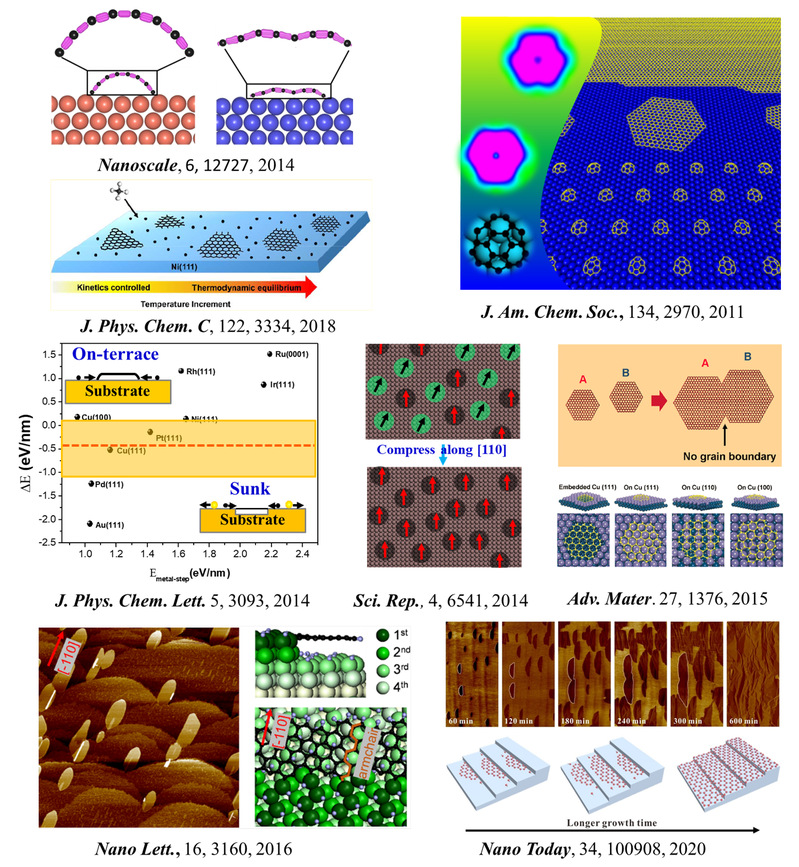

社会兼职研究方向主要研究方向 多年来一直从事新型纳米材料以及固体表面催化的理论研究,在二维材料生长,结构,性质以及固体表面催化机制方面具有较好的研究基础。目前已发表SCI论文60余篇,大部分发表在高水平的期刊杂志上,如物理类顶尖期刊Phys. Rev. Lett.,化学类顶尖期刊J. Am. Chem. Soc.,Angew. Chem. Int. Ed.,ACS Nano,材料类顶尖期刊Nat. Mater., Nat. Electron. Adv. Mater.,Adv. Funct. Mater.,以及Nature Commun.等。理论研究工作受到国内外同行的广泛关注,被国外媒体网站广泛报导及著名期刊Science, PNAS等引用。 具体研究方向为: 一.新型纳米材料结构及性质调控 我们的理论研究发现,可将石墨烯纳米带直立在各种衬底上(如金刚石,金属催化剂等),并且直立的石墨烯纳米带在金刚石衬底上可以保持其独立的电子性质。由于单个石墨烯阵列之间的间距可以窄到1nm左右,因此可利用该石墨烯纳米带阵列来制作高密度电子器件,用该办法合成出来的场致发射器的电子密度理论上可达到1013cm-2。这一研究结果发表在J. Am. Chem. Soc.133, 16072, 2011. 此外,对石墨烯进行氮掺杂也是打开石墨烯带隙、提高自由载流子密度的重要手段之一。为此,我们研究了碳氮二维材料的结构及性质,发现碳氮二维材料的结构特征与氮浓度密切相关。高氮浓度的结构有利于吡啶氮的形成,低氮浓度下则易于形成石墨氮与吡啶氮共存的结构。此外,我们还发现低氮浓度的结构在一定的C和N化学势下具有更好的能量优势。这些发现很好地解释了目前实验上石墨烯掺氮浓度较低及掺氮类型不可控的本质原因。研究结果发表在npj Comput. Mater., 6, 128, 2020. 用普通掺杂方法所获得氮掺杂石墨烯往往呈现石墨氮,吡啶氮,吡咯氮等多种类型氮原子共掺杂的现象(图29a,c)。而用乙腈作为碳氮源以及在氧气刻蚀的条件下可获得氮团簇掺杂的石墨烯,并且其中只含有石墨氮。这种氮团簇掺杂后的石墨烯迁移率高达13000cm2/Vs,比其他工艺制备的掺杂石墨烯要高出数个量级。同时,石墨烯的面电阻也降低到130 oh/sq,掺杂的稳定性显著提高。低温和磁场下,可以观察到氮团簇形成的较强的库伦电势导致的震荡(图32),这也从侧面证实了团簇掺杂的存在。相较于其他材料,簇状氮掺杂的石墨烯继承了本征石墨烯较低的面电阻和较高的可见光透过率的特点。且与吸附掺杂相比,簇状氮掺杂石墨烯的高温稳定性更好。簇状氮掺杂石墨烯基于其良好的透光性、导电性、稳定性和高载流子迁移率,(图31)为未来石墨烯研究和产业应用提供了材料基础,具有重要的基础科学意义和应用价值。该项工作发表在Sci. Adv. 5, eaaw8337, 2019。

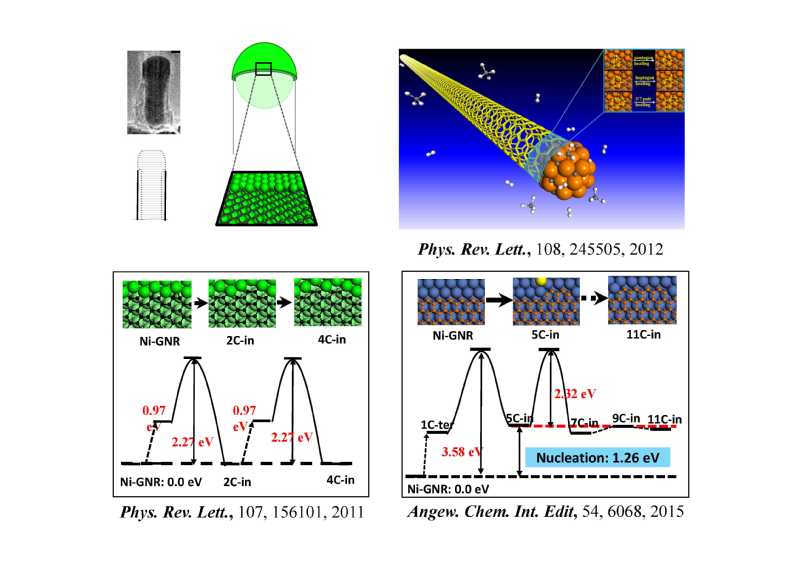

二.低维纳米材料的生长机制 1. 碳纳米管CVD生长机制及缺陷消除 我们通过理论计算提出碳纳米管生长的决速步是碳原子从金属催化剂表面加入到碳纳米管并成为碳管一部分的过程。通过考察Armchair型碳纳米管在Fe,Co,Ni这三种催化剂表面的生长速度,我们发现Fe是碳纳米管高速生长的优良催化剂。在1300K的温度下,Armchair型碳纳米管在Fe催化剂表面的生长速度可达到106 nm/s,这与目前绝大部分的实验结果一致。 与Armchair碳纳米管不同,Zigzag碳纳米管的每一环碳原子的生长都需要经历一个成核过程,因此其生长速度大大低于Armchair及其它类型的手性碳纳米管。生长温度在1000K左右时,Zigzag碳纳米管在Fe,Co,Ni催化剂表面的生长速度分别为Armchair碳纳米管的10-3,10-4,10-5。此外,Zigzag碳纳米管的生长速度还与其管径大小密切相关。 碳纳米管的电子性质与其手性有很大关系,生长过程中保持特定的手性对实现其在电子器件领域的应用具有非常重要的意义。基于理论分析和计算,我们提出碳纳米管生长过程中最有可能的拓扑缺陷是五元环和七元环成对的缺陷(五/七缺陷对),一定温度下,碳纳米管中的五/七缺陷对浓度可低至10-11,即cm长度的碳管内没有任何缺陷。该研究结果发表在Phys. Rev. Lett. 108, 245505, 2012。已被Science, PNAS等多个著名杂志引用,并引起了包括美国自然科学基金网等众多国外媒体网站的关注和报导。

我们的理论计算表明,可将石墨烯纳米带直立金刚石衬底上,并且石墨烯纳米带在金刚石衬底上发生直立后仍然能保持其原来的电子性质。由于单个石墨烯阵列之间的间距可以窄到~1nm,因此可利用石墨烯阵列来制作高密度电子器件,用该办法合成出来的场致发射器的电子密度理论上可达到1013cm-2。这一研究结果发表在化学类顶尖杂志J. Am. Chem. Soc. 133, 16072, 2011。并引起国际同行及媒体的广泛关注,有超过50家国外媒体和网站对该研究结果进行了报导。 石墨烯生长过程中存在一个含有三个五元环的C21幻数结构,其存在的主要原因是由于其结构的高对称性,以及边缘C原子与金属衬底的强相互作用。这一发现合理地解释了石墨烯成核早期实验上所观测到的在金属表面大小均匀的碳原子幻数团簇。研究成果发表在J. Am. Chem. Soc.134, 2970, 2012。 我们基于理论计算结果预测,根据金属催化剂衬底的性质不同,石墨烯在其表面生长所采取的生长模式也不一样,分别有平台生长(on-terrace growth),台阶生长(step-derived growth)以及嵌入生长(self-embedded growth)三种可能的模式。生长模式的不同会导致石墨烯生长取向的不一样。这一预测结果已被韩国著名实验小组证实,合作研究成果发表在Adv. Mater. 27, 1376, 2015。 考虑到石墨烯的台阶生长模式影响石墨烯的生长取向,我们与中科院微系统信息与技术研究所的实验课题组合作,通过在Ge(110)和Ge(100)表面产生台阶实现了石墨烯的定向生长。我们对石墨烯在Ge(110)和Ge(100)表面的生长模式进行了研究,进一步验证了我们关于台阶生长模式的理论预测。我们的合作研究论文分别发表在Nano Letters, 16, 3160, 2016和Nano Today, 34, 100908, 2020。

三. 固体表面催化 1. 铝团簇表面小分子催化 结合密度泛函理论,高精度的后自洽场计算方法以及从头算的分子动力学方法,我们对金属及半导体表面化学催化进行了探讨。发现某些金属纳米团簇的表面与大块金属表面具有类似的表面性质及相似的催化机制。首次提出DFT计算在处理小分子与金属铝表面的化学吸附时,由于存在自相互作用误差(SIE)而大大低估了反应的势垒,解释了长期以来关于铝金属表面小分子理论计算和实验得出不一致结论的根本原因。

2. Si(100)表面氢脱附及重构

招生与培养开授课程

《低维物理》

科研项目1. 国家自然科学基金委员会,青年项目,21303056,催化剂衬底对石墨烯CVD 生长的影响,2013-01至2015-12,30万元,主持,已结题; 2. 催化剂衬底对石墨烯CVD生长的影响,上海市浦江人才计划项目,2013-09至2015-08,金额:20万,主持; 3. 锗表面石墨烯生长机制研究,中国科学院微系统与信息技术研究所,信息功能材料国家重点实验室开放课题,2014-04至2016-03,金额:10万,主持。 4. 国家自然科学基金委员会,面上项目,21673075,适合石墨烯,六方硼氮石墨烯化学气相沉积法生长的合金催化剂的理论设计,2017-01至2020-12,65万元,主持,已结题; 5. 国家自然科学基金委员会,面上项目,22173031,在金属硼化物上实现大面积、层数可控单晶六方氮化硼外延生长的可行性理论研究,2022-01至2025-12,60万元,主持; 6. 国家重点研发计划“纳米前沿”重点专项“二硫化钨晶圆可控制备、多维度表征和可集成光源器件构筑”项目“高质量单层二硫化钨晶圆可控制备”,2021YFA1200800,2021-12至2026-11,主要参与人。 学术成果62. P. Li, W. Wei, M. Zhang, Y. Mei, P. K. Chu, X. Xie, Q. Yuan,* Zengfeng Di,* “Wafer-Scale Growth of Single-Crystal Graphene on Vicinal Ge(001) Substrate,”Nano Today, 34, 100908, 2020. (IF= 20.72) 61. Y. Yin, V. Gladkikh, P. Li, L. Zhang, Q. Yuan,* and F Ding,* “Stabilities of Isomers of Phosphorus on Transition Metal Substrates”, Chem. Mater. 33, 9447–9453, 2021. (IF=9.811) 60. X. Liu, J. Zhang, W. Wang, W. Zhao, H. Chen, B. Liu, M. Zhang, F. Liang, L. Zhang, R. Zhang, N. Li, Y. Zhang, Y. Liu, K. Jia, L. Sun, Y. Zhao, P. Gao, Q. Yuan, L. Lin, H. Peng, Z. Liu,* “The role of Cu crystallographic orientations towards growing super-clean graphene on meter-sized scale”, Nano Research, 1-6, 2021. (IF=8.897) 59. W. Wu, L. Bai, Yenan Song*, Y. Su, K. Jiang, H. Sun, G. Zhen, Y. Shen, Q. Yuan, Z. Sun*, “Defect-Engineered Graphene Films as Ozonation Catalysts for the Devastation of Sulfamethoxazole: Insights into the Active Sites and Oxidation Mechanism”, ACS Appl. Mater. Interfaces 13, 52706, 2021. (IF=9.229) 58. Y. Yang, W. Wei, P. He, S. Yang,* Q. Yuan, G. Ding,* Z. Liu,* X. Xie, “Stacking driven Raman spectra change of carbon based 2D semiconductor C3N”,Chin. Chem. Lett., https://doi.org/10.1016/j.cclet.2021.09.098, 2021. (IF=6.779) 57. A. Baktash, B. Demir, Q. Yuan, D. J Searles,* “Effect of defects and defect distribution on Li-diffusion and elastic properties of anti-perovskite Li3OCl solid electrolyte”, Energy Stor. Mater., 41, 614, 2021. (IF=17.789) 56. S. Zhao, K. Yan, J.u Liang, Q. Yuan, J. Zhang, B. Sun,* P. Munroe, G. Wang,* “Phosphorus and “Oxygen Dual‐Doped Porous Carbon Spheres with Enhanced Reaction Kinetics as Anode Materials for High‐Performance Potassium‐Ion Hybrid Capacitors”, Adv. Funct. Mater., 31, 2102060, 2021. (IF=18.808) 55. T. L. Wan, L. Ge, Y. Pan, Q. Yuan, L. Liu, S. Sarina, L. Kou,* Catalysis based on ferroelectrics: controllable chemical reaction with boosted efficiency, Nanoscale, 13, 7096, 2021. (IF=7.790) 54. Y. Yin, H. Chen,* Q. Yuan,* “Strain-Induced Bandgap Engineering in C3N Nanotubes” Chem. Phys. Lett., 138390, 2021. (IF=2.03) 53. H.S. Wang, L. Chen, K. Elibol, L. He, H. Wang,* C. Chen, C. Jiang, C. Li, T. Wu, Chun X. Cong, T. J. Pennycook, G. Argentero, D. Zhang, K. Watanabe, T. Taniguchi, W. Wei, Q. Yuan, J. C. Meyer,* X. Xie, “Towards chirality control of graphene nanoribbons embedded in hexagonal boron nitride”, Nat. Mater., s41563-020-00806-2, 2020. (IF=38.887) 52. S. Bu, N. Yao, M. A. Hunter, D. J. Searles,*Q. Yuan,* “Design of Two-dimensional Carbon-Nitride Structures by Tuning the Nitrogen Concentration” NPJ Comput. Mater., 6, 128, 2020. (IF=9.341 ) 51. R. Jiang, Z. Shi, W. Zhao, B. Gao, T. Wu,* Q. Yuan,* “Vacancy-Assisted Growth Mechanism of Multilayer Hexagonal Boron Nitride on a Fe2B Substrate” J. Phys. Chem. Lett. 11, 8511, 2020. (IF=6.71 ) 50. J. Liu, X. Liao, J. Liang, M. Wang,Q. Yuan,* “Tuning the electronic properties of hydrogen passivated C3N nanoribbons through van der Waals stacking”, Front. Phys., 15, 63503, 2020. (IF=2.502) 49. G. L. L. Fraga, Y. Yin, M. Konarova, MD M. Hasan, B. Laycock, Q. Yuan, Nuno Batalha,* Steven Pratt, “Hydrocarbon hydrogen carriers for catalytic transfer hydrogenation of guaiacol International Journal of Hydrogen Energy”, Int. J. Hydrogen Energ. accepted, 2020. (IF=4.939) 48. K. Yi, Z. Jin, S. Bu, D. Wang, D. Liu, Y. Huang, Y. Dong, Q. Yuan, Y. Liu, A. T. S. Wee, D. Wei, “Catalyst-Free Growth of Two-Dimensional BCxN Materials on Dielectrics by Temperature-Dependent Plasma-Enhanced Chemical Vapor Deposition”, ACS Appl. Mater. Interfaces, 12, 33113, 2020. (IF= 8.758) 47. P. Li, W. Wei, M. Zhang, Y. Mei, P. K. Chu, X. Xie, Q. Yuan,* Zengfeng Di,* “Wafer-Scale Growth of Single-Crystal Graphene on Vicinal Ge(001) Substrate,”Nano Today, 34, 100908, 2020. (IF= 16.907) 46. Q. Zhao, W. Zhao, C. Zhang, Y. Wu, Q. Yuan, A.K. Whittaker, X.S. Zhao,* “Sodium-ion storage mechanism in triquinoxalinylene and a strategy for improving electrode stability,” Energy Fuels, 34, 5099, 2020. (IF=3.421 ) 45. A Baktash, JC Reid,Q Yuan, T Roman, DJ Searles*, “Shaping the Future of Solid‐State Electrolytes through Computational Modeling,” Adv. Mater., 32, 1908041, 2020. (IF=25.809 ) 44. Y. Liu, L. Zeng, C. Xu, F. Geng, M. Shen, Q. Yuan, B. Hu,* “Optimizing the Ueff value for DFT+U calculation of paramagnetic solid-state NMR shifts by double Fermi-contact-shift verification,” Chem. Phys. Lett., 736, 136779, 2019. (IF= 2.029) 43. S. Wu, W. Zhao, X. Yang, Y. Chen, W. Wu, Y. Song,* Q. Yuan,* “Suitable Surface Oxygen Concentration on Copper Contributes to the Growth of Large Graphene Single Crystal,” J. Phys. Chem. Lett. 10, 4868, 2019. (IF=6.71) 42. L. Lin,+ J. Li,+Q. Yuan,+ Q. Li,+ J. Zhang, L. Sun, D. Rui, Z. Chen, K. Jia, M. Wang, Y. Zhang, M. H. Rummeli, N. Kang, H. Q. Xu*, F. Ding*, H. Peng*, Z. Liu*, “Nitrogen cluster doping for high-mobility/conductivity graphene films with millimeter-sized domains,” Sci. Adv. 5, eaaw8337, 2019. (co-first author, IF=12.804) 41. J. Zhang, K. Jia, L. Lin, W. Zhao, H. T. Quang, L. Sun, T. Li, Z. Li, X. Liu, L. Zheng, R. Xue, J. Gao, Z. Luo, M. H Rummeli,Q. Yuan, H. Peng,* Z. Liu,* “Large-area synthesis of super-clean graphene via selective etching of amorphous carbon by carbon dioxide,” Angew. Chem. Int. Edit. 58, 14446, 2019. (IF=12.257) 40. M. Hunter, J. M. T. A. Fischer, Q. Yuan, M. Hankel, D. J. Searles,* “Evaluating the Catalytic Efficiency of Paired, Single-atom Catalysts for the Oxygen Reduction Reaction,” ACS Catal. 9, 7660−7667, 2019. (IF=12.221) 39. M. Hunter, J. M. T. A. Fischer, M. Hankel, Q. Yuan, D. J Searles,* “Doping Effects on the Performance of Paired Metal Catalysts for the Hydrogen Evolution Reaction,” J. Chem. Inf. Model., 59, 2242-2247, 2019. (IF=3.966) 38. W. Zhang, S. Bu, Q. Yuan,* Q. Xu, M. Hu,* “Controllable Nitrogen-Doping of Nanoporous Carbons Enabled by Coordination Frameworks,” J. Mater. Chem. A, 7, 647-656, 2019. (IF=10.733) 37. J. Tian, B. Ma, S. Bu, Q. Yuan,* C. Zhao,* “One-pot synthesis of highly sintering- and coking-resistant Ni nanoparticles encapsulated in dendritic mesoporous SiO2 for methane dry reforming,” Chem. Commun., 54, 13993, 2018. (IF=6.164) 36. C. Gao, Y. Yin, L. Zheng, Y. Liu, S. Sim, Y. He, C. Zhu, Z. Liu, H.W. Lee, Q. Yuan, Seok Woo Lee, “Engineering the Electrochemical Temperature Coefficient for Efficient Low‐Grade Heat Harvesting,” Adv. Funct. Mater. 28, 1803129,2018. (IF=15.621) 35. Y. Liu, T. Wu, Y. Yin, X. Zhang, Q. Yu, D. J. Searles, F. Ding, Q. Yuan,* X. Xie,* “How Low Nucleation Density of Graphene on CuNi Alloy is Achieved,” Adv. Sci. 5, 1700961, 2018. (IF=15.804) 34. D. Wang, Y. Liu, D. Sun, Q. Yuan,* F. Ding,* “Thermodynamics and Kinetics of Graphene Growth on Ni (111) and the Origin of Triangular Shaped Graphene Islands,” J. Phys. Chem. C, 122, 3334–3340, 2018. (IF=4.309) 33. X. Wang,+Q. Yuan,+ J. Li,* F. Ding,* “The transition metal surface dependent methane decomposition in graphene chemical vapor deposition growth,” Nanoscale, 9, 11584-11589, 2017. (co-first author, IF=6.97) 32. J. H. Yang, Q. Yuan, B. I Yakobson, “Chemical Trends of Electronic Properties of Two-Dimensional Halide Perovskites and Their Potential Applications for Electronics and Optoelectronics,” J. Phys. Chem. C, 120, 24682-24687, 2017. (IF=4.309) 31. J. H. Yang, Q. Yuan, H. Deng, S. H. Wei, B. I Yakobson, “Earth-Abundant and Non-Toxic SiX (X = S, Se) Monolayers as Highly Efficient Thermoelectric Materials,” J. Phys. Chem. C, 21, 123-128, 2017. (IF=4.309) 30. J. Dai,+ D. Wang,+ M. Zhang, T. Niu, A. Li, M. Ye, S. Qiao, G. Ding, X. Xie, Y. Wang, P. K. Chu, Q. Yuan,* Z. Di,* X. Wang, F. Ding, B. I Yakobson, “How graphene islands are unidirectionally aligned on Ge(110) surface”, Nano Letters, 16, 3160, 2016. (IF=12.279) 29. Tianru Wu,+ Xuefu Zhang,+Qinghong Yuan,+ Jiachen Xue, Guangyuan Lu, Zhihong Liu, Huishan Wang, Haomin Wang, Feng Ding, Qingkai Yu, Xiaoming Xie* & Mianheng Jiang, “Fast growth of inch-sized single-crystalline graphene from a controlled single nucleus on Cu–Ni alloys”, Nat. Mater., 15, 43–47, 2016. (co-first author) 28. Xiuyun Zhang, Ziwei Xu, Qinghong Yuan, John Xin, Feng, Ding, “The favourable large misorientation angle grain boundaries in graphene”, Nanoscale, 7, 20082-20088, 2015. 27. Guang-Yao Song, Qing-Hong Yuan, Wen-Xin Hu, De-Yan Sun, “Production of Spin-Semiconducting Zigzag Graphene Nanoribbons by Constructing Asymmetric Notch on Graphene Edges” Mat. Res. Express, 2, 125006, 2015. 26. Wenwei Fu, Man Wu, Lunlun Zhu, Yuanzhi Lao, Liping Wang, Hongsheng Tan, Qinghong Yuan, Hongxi Xu, “Enylated benzoylphloroglucinols and biphenyl derivatives from the leaves of Garcinia multiflora Champ” RSC Advances, 5, 78259-78267, 2015. 25. Gang Wang, Miao Zhang, Su Liu, Xiaoming Xie, Guqiao Ding, Yongqiang Wang, Paul K. Chu, Heng Gao, Wei Ren, Qinghong Yuan, Peihong Zhang, Xi Wang and Zengfeng Di, “Synthesis of Layer-Tunable Graphene: A Combined Kinetic Implantation and Thermal Ejection Approach”, Adv. Funct. Mater., 25, 3666-3675, 2015. (co-corresponding author) 24. Qinghong Yuan,* Feng Ding,* “How a Zigzag Carbon Nanotube Grows” Angew. Chem. Int. Edit, 54, 6068, 2015. 2015. 23. Guangyuan Lu, Tianru Wu, Qinghong Yuan, Huishan Wang , Haomin Wang, Feng Ding, Xiaoming Xie,* Mianheng Jiang, “Synthesis of large single-crystal hexagonal boron nitride grains on Cu-Ni alloy” Nat. Commun., 6, 6160, 2015. 22. Van Luan Nguyen , Bong Gyu Shin , Dinh Loc Duong , Sung Tae Kim , David Perello ,Young Jin Lim , Qing-Hong Yuan , Feng Ding , Hu Young Jeong , Hyeon Suk Shin, Seung Mi Lee , Sang Hoon Chae , Quoc An Vu , Seung Hee Lee , and Young Hee Lee,* “Seamless Stitching of Graphene Domains on Polished Copper (111) Foil” Adv. Mater. 27(8), 1376-1382, 2014. 21. Qinghong Yuan, Feng Ding,* “Formation of Carbyne and Graphyne on Transition Metal Surfaces” Nanoscale, 6(21), 12727-12731, 2014. 20. Qinghong Yuan, Boris I. Yakobson,* and Feng Ding,* “Edge-Catalyst Wetting and Orientation Control of Graphene Growth by Chemical Vapor Deposition Growth”, J. Phys. Chem. Lett. 5(18), 3093−3099, 2014. 19. Qinghong Yuan,* Guangyao Song, Deyan Sun, Feng Ding,* "Formation of Graphene Grain Boundaries on Cu(100) Surface and a Route Towards Their Elimination in Chemical Vapor Deposition Growth", Sci. Rep., 4, 6541, 2014. 18. Xian-Zhi Yao, Zheng Guo, Qing-Hong Yuan, Zhong-Gang Liu, Jin-Huai Liu, and Xing-Jiu Huang,* “Exploiting Differential Electrochemical Stripping Behaviors of Fe3O4 Nanocrystals toward Heavy Metal Ions by Crystal Cutting”, ACS Appl. Mater. Interfaces, 6(15), 12203–12213, 2014. 17. WenqianWu, YangYang, Qinghong Yuan, Deyan Sun,* “The collapse of an elastic tube induced by encapsulated liquid droplets”, SOFT MATTER, 9(41), 9774-9779, 2013. 16. Haixin Chang, Zhenhua Sun, Mitsuhiro Saito, Qinghong Yuan, Han Zhang, et. al. “Regulating Infrared Photoresponses in Reduced Graphene Oxide Phototransistors by Defect and Atomic Structure Control”, ACS NANO, 7(7), 6310-6320, 2013. 15. Qinghong Yuan, Li Li, Qianshu Li, Feng Ding,* “The Effect of Metal Impurities on the Tensile Strength of Carbon Nanotubes: A Theoretical Study”, J. Phys. Chem. C, 117(10), 5470–5474, 2013. 14. Qinghong Yuan, ZhipingXu, Boris Yakobson, Feng Ding,* “Efficient Defect Healing in Catalytic Carbon Nanotube Growth”,Phys. Rev. Lett., 108 (24), 245505, 2012. 13. Qinghong Yuan, Zhifeng Liu,* “Reply to the ‘Comment on “Dynamic factors in the reactions between the magic cluster Al13- and HCl/HI”: A wavefunction instability problem.”, Phys. Chem. Chem. Phys., 14 (18), 6641-6642, 2012. 12. Qinghong Yuan, Junfeng Gao, Haibo Shu, Jijun Zhao,* Xiaoshuang Chen,* Feng Ding,* “Magic Carbon Clusters in the Chemical Vapor Deposition (CVD) Growth of Graphene”, J. Am. Chem. Soc., 134 (6), 2970-2975, 2012. 11. Qinghong Yuan, Hong Hu, Feng Ding,* “Threshold Barrier of Carbon Nanotube Growth”, Phys. Rev. Lett., 107(15), 156101, 2011. 10. Qinghong Yuan, Hong Hu, Junfeng Gao, Feng Ding,* Zhifeng Liu, Boris Yakobson,* “Upright Standing Graphene Formation on Substrates ”, J. Am. Chem. Soc., 133 (40), 16072-16079, 2011. 9. Junfeng Gao, Qinghong Yuan, Hung Hu, Jijun Zhao, Feng Ding,* “Formation of Carbon Clusters in the Initial Stage of Chemical Vapor Deposition Graphene Growth on Ni(111) Surface”, J. Phys. Chem. C, 115(36), 17695-17703, 2011. (co-first author) 8. Qinghong Yuan, Jiabo. Li, and Zhi-feng Liu,* “Dynamic factors in the reaction between the magic cluster Al13- and HCl/HI” Phys. Chem. Chem. Phys., 13(20), 9871-9879, 2011. 7. Jinlan Wang, Liang Ma, Qinghong Yuan, Liyan Zhu, and Feng Ding,* “Transition Metal Catalyzed Unzipping Single-Walled Carbon Nanotubes into Narrow Graphene Ribbons at Low Temperature”, 2011, Angew. Chem. Int. Edit, 50(35), 8041, 2011. 6. Q.J. Zhang, B. Li, Q.H. Yuan, BH Li, Z.F. Liu, L.A. Chen, “The isomeric effect on the adjacent Si dimer didechlorination of trans and iso-dichloroethylene on Si(100)-2 x 1”, Phys. Chem. Chem. Phys., 13(15), 7090, 2011. 5. Q.H Yuan, J.B. Li, X.L. Fan, W.M. Lau and Zhi-Feng Liu.,* “A barrier for the Al13-+O2 reaction and its implication for the chemisorption of O2 on Al(111)” Chem. Phys. Lett., 489(1-3), 16-19, 2010. 4. Q.H. Yuan, Q.S. Li, K.D. Wang, Zhi-feng Liu, “An intermediate in the STM tip-induced atomic process on H/Si(100) surfaces: theoretical investigation” Phys. Rev. B, 81(20), 205301, 2010. 3. H.X. Chang, Z.H. Sun, Q.H. Yuan, F. Ding, X.M. Tao, F. Yan, Z.J. Zheng, “Thin Film Field-Effect Phototransistors from Bandgap-Tunable, Solution-Processed, Few-Layer Reduced Graphene Oxide Films”, Adv. Mater., 22(43), 4872-4876, 2010. 2. X. Lu, Q.H. Yuan, Q. Zhang, “Sidewall-Epoxidation of Single-Walled Carbon Nanotubes: A Theoretical Prediction.” Org. Lett., 5(19), 3527-3530, 2003. 1. X. Lu,* X.L. Wang, Q.H. Yuan, “Diradical mechanisms for the cycloaddition reactions of 1,3-butadiene, benzene, thiophene, ethylene, and acetylene on a Si(111)-7x7 surface.” J AM. CHEM. SOC., 125(26), 7923-7929, 2003. 荣誉及奖励•2013年入选上海市浦江人才计划 •2015年入选华东师范大学紫江青年学者 •2016年入选澳大利亚DECRA人才计划 |

|

袁清红 |

2

2